Industrial hall ventilation

In industry, we encounter different requirements for ventilation methods. The choice of a suitable system depends on the technology and industry. Some industrial processes require extremely precise material processing temperatures, while other production halls may require a huge amount of cooling capacity to create a suitable working environment for workers, while other industries require short-term moisture retention. Another type of technology or production may require so-called "clean rooms", where the air is exceptionally clean and filtered.

Energy systems, including ventilation, must be adapted to the type and specifics of production. Through the competent energy consulting of the Adrian Group, it is possible to save large sums of money. Energy savings in this sector can also be seen as a profit, which is reflected in low monthly operating costs.

Great potential for energy savings can be achieved by setting up the ventilation system correctly without affecting the efficiency of the cooling or heating system.

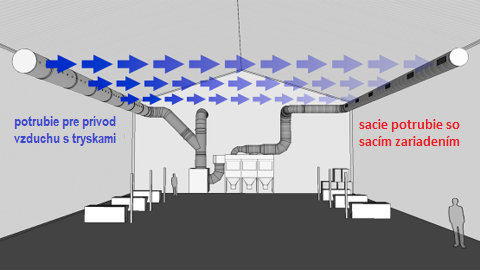

With mixing ventilation, clean air is supplied to the upper part of the hall, which results in mixing air in the hall.

Example: welding wire consumption <10 tons / year, low heat load:

- hall height <7.5 m,

- high-current feed nozzles,

- two pipes facing each other,

- system suitable for cooling and heating,

- eliminates dust and odors.

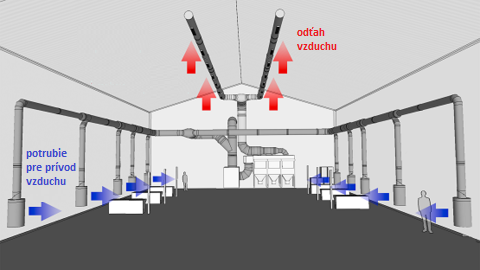

With layered ventilation, clean air is supplied through source vents near the floor.

Example: welding wire consumption> 10 tons / year, high heat load:

- hall height ≥ 7.5 m,

- discharge openings near the floor to generate a layer of cold air,

- sensors for continuous temperature measurement and fully automatic control of the fresh air content,

- just a small air flow,

- system suitable for cooling and heating,

- adequate heat loss,

- suitable for eliminating dust and odors.