Gas burners

Riello gas burners are designed to meet the requirements of all industrial applications. Production takes place in accordance with high standards of quality management, which is a guarantee of their functional safety.

Characteristics of gas burners

During the development of these burners, special attention was paid to reducing noise levels, minimizing dimensions, ease of installation and adjustment. The advantage of gas burners is their size. Due to their small size, they can be used in all types of boilers, heaters and infrared heaters available on the market.

Approval of gas burners

All models are approved by the European standard EN 676 and comply with the European directives on electromagnetic compatibility, low voltage, efficiency of machines and boilers. All gas burners offered by Adrian Group are tested before leaving the Riello production plant.

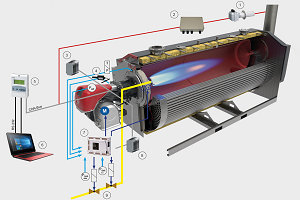

Types of gas burners

We offer a complete range of burners and accessories with a power range of 10 kW to 20 MW. These products can burn oil or gas fuels, as well as biofuels. Depending on the design, we offer:

Single-stage gas burners

The operation is secured by "single stage" combustion head, which can be adjusted based on the required power. It enables optimum performance, ensures good combustion and reduces fuel consumption. The GAS series are extremely reliable burners that are easy to use and operate without special maintenance. Simplified maintenance is achieved by a sliding bar system, which allows easy access to all basic components of the combustion head. All electrical components are easily accessible after removing the protective panel, which guarantees quick and easy intervention in the components.

Two-stage gas burners

The operation is "two-stage"; the burners are equipped with a control panel on the microprocessor, which provides an indication of the condition of the burners and the causes of faults. The optimization of sound emissions is guaranteed by the special design of the air intake circuit. The higher power of the fans and the combustion head guarantees flexibility of use and excellent work at all speeds.

Modular gas burners

Operation can be "two-stage progressive" or alternatively "modulated" by installing a PID logic controller and appropriate probes. The RL / M series burners guarantee a high level of efficiency in all applications, thus reducing fuel consumption and operating costs. Optimization of sound emissions is guaranteed by the use of forward-bladed fans and sound-insulating material integrated in the air intake circuit.

Burner modulation can be performed using mechanical, electronic cams or gas proportional valves. Depending on the use of the head, we can offer burners with standard or reduced NOx value.

Corrosive Environment Challenges and Solutions at Bekaert Hlohovec

The indoor environment plays a crucial role in the longevity of technical equipment. Our client, Bekaert Hlohovec, a.s., specializes in producing iron wires, which are immersed in sulfuric acid and lime water during the manufacturing process. This creates a highly corrosive atmosphere, which severely impacts even durable materials like aluminum and stainless steel.

The Riello RS25 M/BLU burners installed on the wire dryers have been particularly affected. After just one year of operation, these burners show wear and tear that typically takes a decade. One of the burners even failed to start.

Upon inspection, we discovered the issue was due to a faulty air pressure measurement nozzle on the fan. Bekaert is aware of the challenges posed by the environment and has taken steps to mitigate the damage. They are covering the burners and sourcing fresh air from outside the hall to reduce the intake of corrosive air from the production area.